8 differences between DC contactors and AC contactors and precautions for use

Datetime: 2/28/2023 1:26:00 PM Visit: 3885

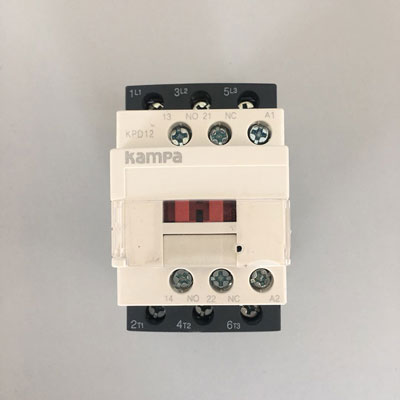

In the automatic control system, there is a very important component, which is the contactor. Its function is very important. It can connect and cut off the circuit, and it can also play a protective role at low voltage. Even under frequent operation, It will not damage the components either. The contactors are mainly divided into AC and DC, so what are the differences between DC contactors and AC contactors? Let's take a look at the AC contactor manufacturers together.

The difference between a DC contactor and an AC contactor lies in the iron core, arc extinguishing system, the number of coil turns, and operating frequency. The DC contactor has no iron core, it is a magnetic blowing arc extinguishing device, the number of coil turns is large, and the operating frequency can reach 2000 times per hour; while the AC contactor will cause core loss, it is a grid arc extinguishing device, and the coil turns The number is small, and the operating frequency is about 600 times per hour.

(1) Look at the nameplate: the coil voltage of most contactors is marked, some are on the coil, and there is a sign plate. These marks not only mark the voltage level but also mark the voltage type. AC is AC voltage, and DC is DC-type voltage.

(2) Arc extinguishing cover: Most AC contactors use grid arc extinguishing devices, but DC contactors use magnetic-blowing arc extinguishing devices.

(3) Coil: The AC contactor has fewer coil turns and lower resistance, while the DC contactor has more coil turns and higher resistance. The AC contactor uses alternating current to eliminate the vibration generated by the electromagnet. and noise, a short-circuit ring is embedded in the static iron core, but the DC contactor does not need it.

(4) Number of poles: AC main pole three, DC main pole two,

(5) The iron core and armature of the coil: the AC is a piece of silicon steel sheet, and the DC is an integral type. The iron core of the AC contactor is made of laminated silicon steel sheets insulated from each other, and is made into a double E shape; the iron core of the DC contactor is made of a whole piece of soft iron, mostly U-shaped.

(6) AC contactors are used to break AC circuits, while DC contactors are used to break DC circuits.

(7) The large starting current of the AC contactor is not suitable for frequent starting and disconnection. The operating frequency is up to 600 times/h, while the operating frequency of the DC contactor can be as high as 2000 times/h.

(8) The use cost of an AC contactor is low and the use cost of a DC contactor is high.

What problems should be paid attention to when using AC contactors?

(1) Check parts regularly

During the use of the contactor, pay attention to regular inspections, especially the various parts inside, to see if there is any looseness and whether the movable parts are flexible. If any parts are damaged, they must be repaired in time.

(2) Keep it clean

The surface of the contact point of the contactor must be kept clean. If there is oil on the surface, it must be cleaned in time, otherwise, it is easy to cause problems such as arc ablation and wear, and it will aggravate the thinning of the contact. Once the contact When the thickness is only one-third of the original, it needs to be replaced.

(3) Pay attention to the correct use

The contractor needs to be very careful when using it. It cannot be used without an arc extinguishing cover, otherwise, it is easy to cause a short circuit problem. The arc extinguishing cover is easily broken because it is made of clay, so it must be disassembled when disassembling. Pay attention to avoid collision damage and so on.

The working principle of the contactor is: when the contactor coil is energized, the coil current will generate a magnetic field, and the generated magnetic field will cause the static iron core to generate electromagnetic attraction to attract the moving iron core, and drive the AC contactor to move, and the normally closed contact will be disconnected. The normally open contact is closed, and the two are linked. When the coil is powered off, the electromagnetic attraction disappears, and the armature is released under the action of the release spring to restore the contacts, the normally open contacts are disconnected, and the normally closed contacts are closed. The working principle of the DC contactor is somewhat similar to that of the temperature switch.

Summary: The above is the difference between the DC contactor and the AC contactor, the precautions for using the AC contactor, and the relevant content of the working principle of the contactor. I hope to bring help to friends in need. If you need to know later For more relevant knowledge, welcome to follow us.